Christmas jumper day is on 8 December 2022, wear a festive jumper and donate money to Save the Children. If you are taking part, please wear your Christmas jumper more than once. It was estimated that 12 million Christmas jumpers were bought in 2019 despite 65 million lurking in the back of the wardrobe according to charity Hubbub. Speaking in The Daily Telegraph, the Charity’s project co-ordinator Sarah Divall suggests customers:

‘Swap, buy second-hand or re-wear and remember a jumper is for life not, just for Christmas.’

Sarah Divall, Hubub

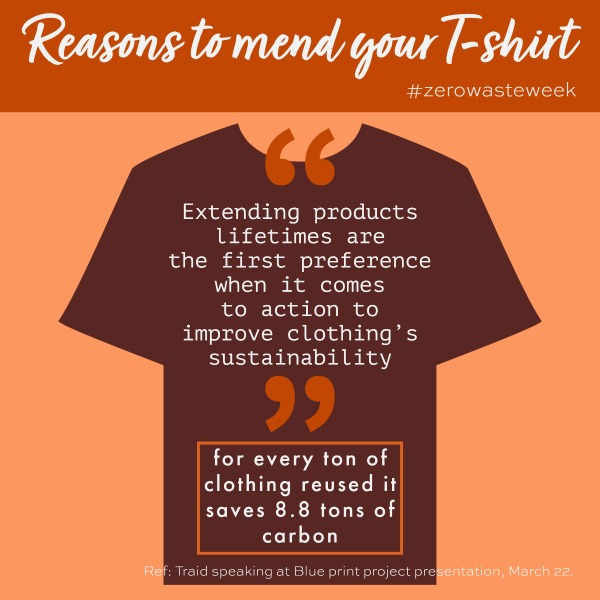

Previously, we have written about the ‘30 wear rule‘ when buying a new item of clothing. Why should a Christmas jumper be any different? Here are our top tips on how to get the most out of your Christmas jumper and prevent it from becoming textile waste.

1. Start wearing your jumper early

I visited my family in Scotland in October, where they have more reason to wear jumpers for longer. It was Halloween but my niece Libby was wearing the above red sweatshirt adorned with snowflakes and an image of a cute black cat and the words ‘Meowy Christmas’. Do you know what, it looked fantastic! The black cat ticked the Halloween box and it was genuinely a warm and item of clothing that she loves and will wear throughout the winter.

2. Worn it before? So What?

My husband went out this evening for his annual Christmas curry club wearing a Christmas Jumper he has owned for 7 years and it is still going. Do you think anyone really remembers if you have worn it before? And if they do, then explain it is your favourite and you are saving another piece of clothing from reaching landfill.

3. Upcycle your Christmas jumper

If tip 2 isn’t quite for you and you want to update your Christmas jumper each year, then add a few embellishments. We love this tip from our friends at the Ealing Repair Cafe. Maria added a Christmas hat to her daughter’s non-Christmas jumper. Add some pompoms, ribbon, sequins. Any small change will make your jumper feel like it is all new again. Of course you can create a Christmas jumper from a plain jumper. As we did at our workshop with The London School of Hygiene and Tropical Medicine back in 2019.

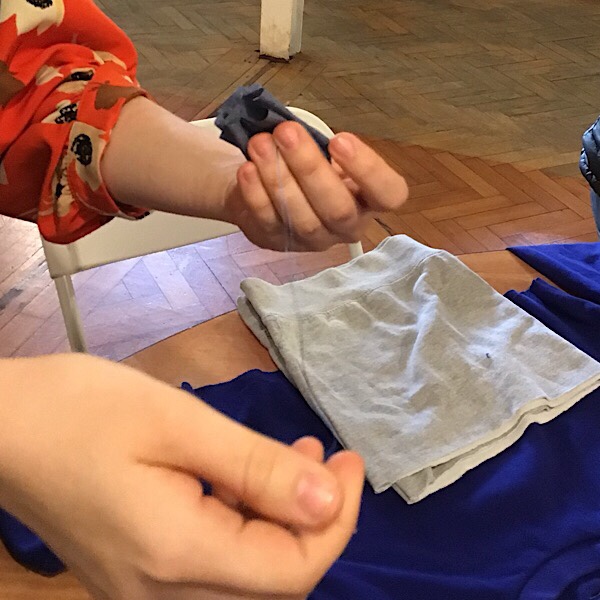

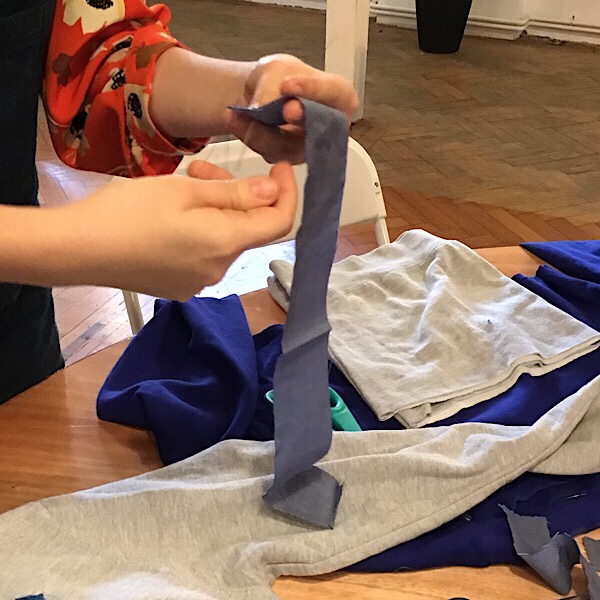

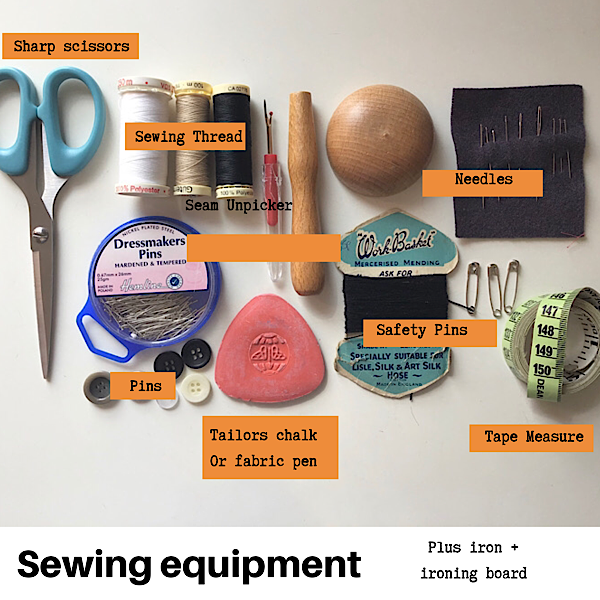

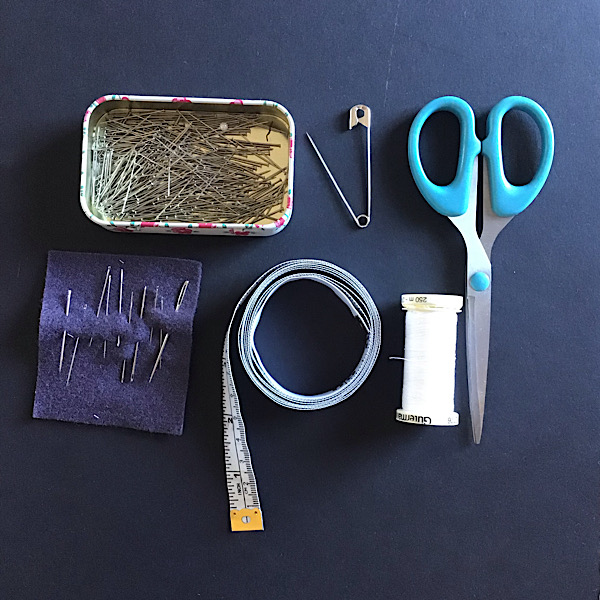

4. Take the Christmas out of your jumper

I’ve seen some really over the top Christmas jumpers, which might be difficult to update to an all-season jumper. In this case, I refer you to points 1 and 2. If your jumper is a bit more subtle, then hide the Christmas references. Eleanor updated this semi-plain sweatshirt by cutting strips of a lightweight fabric. Thread a needle with a double a length of sewing thread approximately 45cm. Knot the end. Fold over the fabric at approximately 5cm folds. Sew through the centre of all the layers. Continue with more lengths of fabric, changing the colours if you wish. Pull together and secure with a couple of back stitches and a knot. Repeat until you have enough ruching to cover the message on your jumper. Alternatively, use the Boro and Sashiko technique to patch over the festivity on your jumper.

5. Swap with a friend

OK, you’ve worn your jumper for 7 years and fancy a change. Find a friend the same clothes size as you and swap your jumpers. Host a Christmas jumper swap with a group of friends or colleagues. Best to do it soon whilst everyone remembers where their jumper is and can wear it over the holidays.

Maybe you haven’t bought a Christmas jumper yet and still thinking about getting into the popular tradition. I spotted the jumpers at the top of this post in the window of my local charity shop and they had lots more inside. Buy from a charity shop-wear-donate-repeat. Use it like a form of rental and the money all goes to charity.